Cuts of Hardwood Flooring

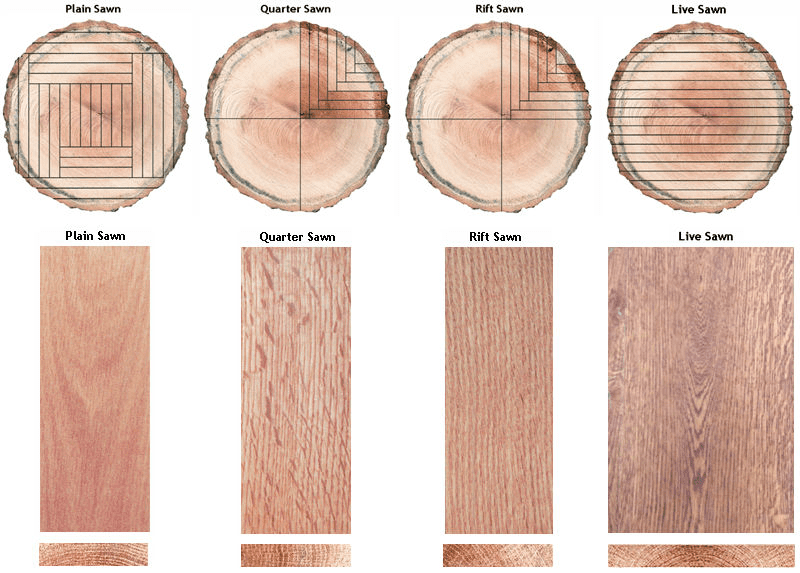

The angle at which a board is cut determines how the finished product looks. Wood flooring is either plain sawn, quarter sawn or rift sawn.

Plain Sawn:

The end grain of a plainsawn board has annual growth rings between 0 and 35 degrees. The face of the board has what is referred to as a “cathedral” grain pattern. Most old homes built in the early and mid-1900s had 2- to 3-inch plainsawn red oak, and when people think of oak floors, this is what they picture. Plain sawn is your commodity flooring cut. It’s quicker to cut and faster to dry.

Quarter Sawn:

When the log is cut into quarters to make quarter-sawn boards, the annual growth rings are at 90° to the surface. White Oak is especially popular in quarter-sawn because the vibrant ray flecks along with the tight wavy grain pattern create a really cool and elegant look. The fleck is caused by the medullary rays, which are the life veins of the tree. The medullary rays are perpendicular to the annual growth rings and therefore parallel to the surface of the quarter-sawn board. These rays are very pronounced in the white oak and it creates this great figure.

Rift Sawn:

This cut has annual growth rings angled around 45°, and the grain pattern on the surface is very lineal. It’s important to note where the riftsawn boards come from in the log. When a log is quartered, it is then cut from the center face and works its way out. The boards that come from the outside edges have 45° annual growth rings. This comes from the smaller part of the quartered wedge. If you picture this, you can see why it is hard to get wide-plank rift only!

Live Sawn:

Live-sawn is cut straight through the log. You can see how the growth rings work their way out from parallel to the surface in the center to perpendicular to the surface on the edges. This creates a very stable floor because it results in a high percentage of R&Q boards. Many people find wide-plank live-sawn a spectacular look because it allows for more of the quarter-sawn and fleck in each board. The wider the plank, the more the natural beauty and larger knots can be represented in the floor. The end result is a unique floor that incorporates all the natural characteristics of the tree and wastes little in the process.

Learn more about how lumber is Sawn to make Hardwood Flooring.